The heart of the RLT concept, the pulse of your business.

The patented computer-controlled blender is the heart of the RLT concept. This professionally-engineered blender was designed and built by industry engineers headed up by William (Red) Lewis (founder and visionary of PDQ Manufacturing®). This engineering group has focused on the same qualities and needs of vehicle wash equipment: reliability, safety, simplicity of controls and environmentally responsible. The RLT blender is the first large-capacity blender ever offered in this industry and meets most local and state requirements.

> The Tools

- Touch screen operation

- Self-loading of all base products

- Self-unloading of all blended products

- Most products require only 1 1/2 hours to process including blending and filling

- One person operation

- Small foot print - 10' X 30'

- Includes safety containment tanks

- (1) 500 gallon & (1) 1,000 gallon tank

> Patented Technology

|

||||

|

|

|

|

||

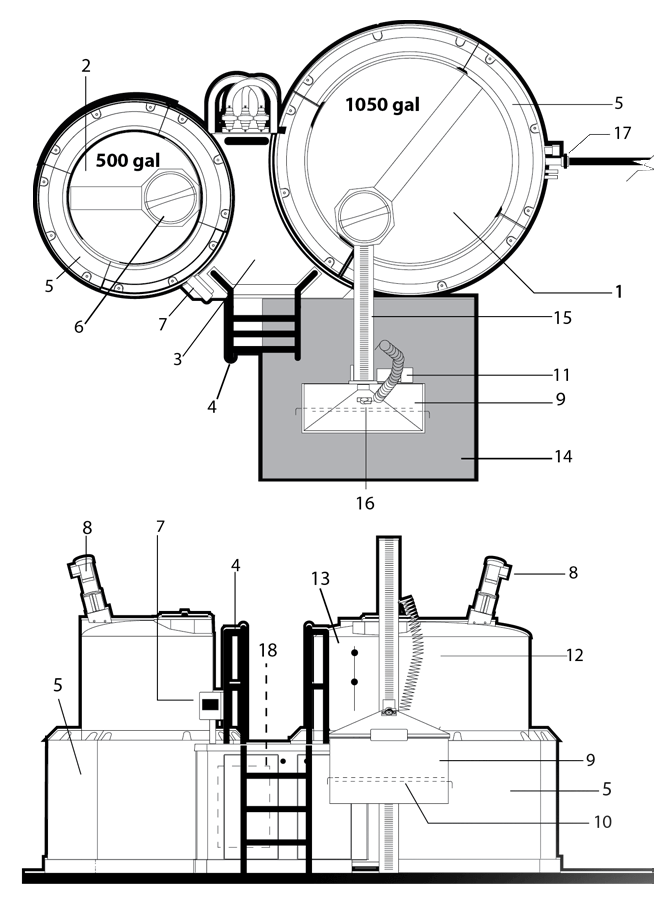

> Blender Specs

> Blender Footprint

> Blender Side View

> Blender Footprint

> Blender Side View

- Detergent Mix Tank #1

- Protection Product Mix Tank #2

- Platform

- Ladder

- Protective Covers

- Lid

- Video Control Screen

- Mixing Motor

- Inverter Container

- Skewers

- Container Drive Mechanism

- Coil Air Line

- Sensors

- Safety Zone

- Inverter

- Vibrator

- Drain Valve

- Processing Unit

- 40 Amp 110 Volt Service

- Phone Line

- Floor Drain

- RO Water System & Holding Tank

- Door Height of 10'

- Ceiling Height of 12'6" for Lift Operation.

- Air Compressor

> Plug & Play Instant Functionality

Unprecedented Ease of Use

The entire philosophy of the blender engineering group was to design a quality, safe and easy to install blending unit. The required support equipment and utilities are easy to install, and in most cases, already available in a typical warehouse or office setting. The blender is pre-wired and plumbed to receive its power, water and air supply. Most blender installs are completed and test-operated the same day if required support items are available.

|

|

|

|